Plastic Troubleshooter

On-Line Solutions To Injection Molding Problems

MACHINE

Melt Temperature Too High Or Too Low

Explanation: Although this may sound contradictory, either condition might cause blushing. If the injection barrel heat is too high, the material will flow too quickly, resulting in slippage of the surface skin, as mentioned above. If the barrel heat is too low, the material may solidify before full packing occurs and the plastic will not be pushed against the mold steel, especially in the gate area because that is the last area to pack.

Solution: Melt temperature must be adjusted to the optimum for a specific material and specific product design.

Low Injection Pressure

Explanation: The plastic material must be injected into the mold in such a way as to cause proper filling and packing while maintaining consistent solidification of the melt. Injection pressure is one of the main control variables of the machine and must be high enough to pack the plastic molecules against the steel of the mold while the plastic cools. Low pressure will not achieve this packing and the material will appear dull in local areas that do not have enough pressure.

Solution: Increasing the injection pressure forces the material against the mold surface, producing a truer finish that replicates the steel finish.

MOLD

Improper Venting

Explanation: Trapped air can cause blushing if the air is trapped in an area that does not compress the air enough to ignite it. The air takes up space where the plastic should be, so the plastic is not forced against the steel finish.

Solution: Vent the mold by grinding thin (0.0005''-0.002'') pathways on the shutoff area of the cavity blocks. Vents should take up approximately 30% of the perimeter of the molded part. Add vents in local areas that show blush. Vent the runner, too. Any air that is trapped in the runner will be pushed into the part.

Small Sprue Bushing Diameter

Explanation: A small sprue-bushing diameter will keep the material from packing because the small opening reduces the ability of the plastic to flow far enough to fill the mold. An unpacked mold will cause blushing where the material is not forced against the mold steel.

Solution: Size the sprue bushing major diameter so its cross-sectional area is equal to (or greater than) the sum of the cross-sectional area of all the runners leading from it. Then, taper the sprue diameter to match the nozzle. That will ensure proper pressure drop adjustments to pack the mold.

MATERIAL

Excessive Moisture

Explanation: In some cases, excessive moisture in a melt will accumulate at the gate area. The reason for this is that the gate area is the last place the pressure builds up. Moisture trapped in other areas may be forced into the gate area due to this pressure buildup. The gate area will appear dull due to the moisture that gets screened out. Usually, this type of blush is accompanied by splay.

Solution: Dry the material to the supplier's recommendations and make sure it is used within two hours of that drying activity.

OPERATOR

Inconsistent Process Cycle

Explanation: It is possible that the machine operator is the cause of delayed or inconsistent cycles. This will result in excessive residence time of the material in the injection barrel. If such a condition exists, materials may fill at a faster speed and cause slippage as explained earlier. Slippage causes blush.

Solution: If possible, run the machine on automatic cycle, using the operator only to interrupt the cycle if an emergency occurs. Use a robot if an ``operator'' is really necessary. And, instruct all employees on the importance of maintaining consistent cycles.

Melt Temperature Too High Or Too Low

Explanation: Although this may sound contradictory, either condition might cause blushing. If the injection barrel heat is too high, the material will flow too quickly, resulting in slippage of the surface skin, as mentioned above. If the barrel heat is too low, the material may solidify before full packing occurs and the plastic will not be pushed against the mold steel, especially in the gate area because that is the last area to pack.

Solution: Melt temperature must be adjusted to the optimum for a specific material and specific product design.

Low Injection Pressure

Explanation: The plastic material must be injected into the mold in such a way as to cause proper filling and packing while maintaining consistent solidification of the melt. Injection pressure is one of the main control variables of the machine and must be high enough to pack the plastic molecules against the steel of the mold while the plastic cools. Low pressure will not achieve this packing and the material will appear dull in local areas that do not have enough pressure.

Solution: Increasing the injection pressure forces the material against the mold surface, producing a truer finish that replicates the steel finish.

MOLD

Improper Venting

Explanation: Trapped air can cause blushing if the air is trapped in an area that does not compress the air enough to ignite it. The air takes up space where the plastic should be, so the plastic is not forced against the steel finish.

Solution: Vent the mold by grinding thin (0.0005''-0.002'') pathways on the shutoff area of the cavity blocks. Vents should take up approximately 30% of the perimeter of the molded part. Add vents in local areas that show blush. Vent the runner, too. Any air that is trapped in the runner will be pushed into the part.

Small Sprue Bushing Diameter

Explanation: A small sprue-bushing diameter will keep the material from packing because the small opening reduces the ability of the plastic to flow far enough to fill the mold. An unpacked mold will cause blushing where the material is not forced against the mold steel.

Solution: Size the sprue bushing major diameter so its cross-sectional area is equal to (or greater than) the sum of the cross-sectional area of all the runners leading from it. Then, taper the sprue diameter to match the nozzle. That will ensure proper pressure drop adjustments to pack the mold.

MATERIAL

Excessive Moisture

Explanation: In some cases, excessive moisture in a melt will accumulate at the gate area. The reason for this is that the gate area is the last place the pressure builds up. Moisture trapped in other areas may be forced into the gate area due to this pressure buildup. The gate area will appear dull due to the moisture that gets screened out. Usually, this type of blush is accompanied by splay.

Solution: Dry the material to the supplier's recommendations and make sure it is used within two hours of that drying activity.

OPERATOR

Inconsistent Process Cycle

Explanation: It is possible that the machine operator is the cause of delayed or inconsistent cycles. This will result in excessive residence time of the material in the injection barrel. If such a condition exists, materials may fill at a faster speed and cause slippage as explained earlier. Slippage causes blush.

Solution: If possible, run the machine on automatic cycle, using the operator only to interrupt the cycle if an emergency occurs. Use a robot if an ``operator'' is really necessary. And, instruct all employees on the importance of maintaining consistent cycles.

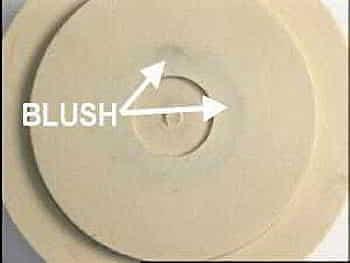

BLUSH

Blush can be defined as a clouded discoloration normally found at gate locations, but they can be found anywhere on the part surface. These visually defective areas have very weak physical properties due to loose molecular structure.

Some common causes and solutions are listed below.

NOTE: For more detailed information on the causes and solutions of this defect you can find it in our BOOK, or ONLINE SEMINAR.

Copyright by IPLAS and Douglas M. Bryce

Worldwide Rights Reserved

.

Worldwide Rights Reserved

.