Plastic Troubleshooter

On-Line Solutions To Injection Molding Problems

MACHINE

Inadequate Cushion

Explanation: A cushion, or pad, of material is needed at the end of the injection stroke so pressure can be held at all times on the material in the mold as it solidifies. This cushion is created by adding a little more material than is actually needed to fill the mold. Without that cushion, the screw will bottom out at the end of injection and will be unable to hold pressure against the material in the cavity. That material will not be packed out and the layers that were formed during injection will not fuse together. As the part cools and shrinks outside of the mold (after ejection), the layers will pull apart causing delamination.

Solution: Establish a cushion of at least 1/8'' and not more than 1/4''. Too little a cushion causes under-packing while too great a cushion results in uncontrolled packing of the sprue area.

Injection Hold Time Too Short

Explanation: Holding pressure is applied at the end of the injection stroke. The holding pressure is used for maintaining pressure against the molten material to pack it together while the skin solidifies. If the holding pressure is stopped too early, the still-molten material will leak back out of the cavity and pressure will be lost. Without the pressure, the layers of plastic cannot be fused together and they will pull apart as the molded part cools and shrinks.

Solution: Maintain the holding pressure until the gate freezes. Once that happens, the holding pressure will no longer have any effect on the material in the cavity.

MOLD

Sharp Corners In Gates And Runners

Explanation: Sharp corners, or 90 degree bends that are positioned along the flow path of runner system and gate, will shear the plastic as it goes by and tear the molecules apart. Breaking this bond results in the individual layers cooling at different rates and not bonding back together again in a proper manner. Delamination occurs when the part cools and shrinks.

Solution: It is always a good idea to utilize a radius at every turn in a runner system and at each gate entrance to the cavity. This will help to minimize shear and reduce the chance of resin separation during injection.

MATERIAL

Excessive Moisture

Explanation: Excessive moisture is one cause of delamination. It occurs because the water droplets actually turn to steam when heated in the injection unit, and this steam explodes throughout the plastic, interfering with molecular bonding, causing voided areas between molecules. This causes those areas to be extremely weak and brittle. The voided areas easily pull apart and delaminate when the part cools and shrinks.

Solution: Although it is commonly understood that non-hygroscopic material does not require drying, do not take chances. Dry all materials. It may be that fillers used in the material ARE hygroscopic and they will absorb moisture. Every plastic material requires specific drying conditions. And each material should be dried according to the material suppliers recommendations. The desired moisture content is between 1/10th of 1 percent and 1/20th of 1 percent by weight. This means the dry air being used to take moisture from the material should have a dew point of -20 to -40 degrees F.

OPERATOR

Excessive Mold Release

Explanation: Machine operators, who have been told to use mold release sprays sparingly, will eventually overuse the spray. The thought seems to be that if a little bit works, a lot will work better. Excessive mold release will interfere with molecular bonding of the plastic and cause weak layers that pull apart easily.

Solution: The remedy is to keep the mold as clean as possible and make every effort to eliminate the use of external mold releases.

Inadequate Cushion

Explanation: A cushion, or pad, of material is needed at the end of the injection stroke so pressure can be held at all times on the material in the mold as it solidifies. This cushion is created by adding a little more material than is actually needed to fill the mold. Without that cushion, the screw will bottom out at the end of injection and will be unable to hold pressure against the material in the cavity. That material will not be packed out and the layers that were formed during injection will not fuse together. As the part cools and shrinks outside of the mold (after ejection), the layers will pull apart causing delamination.

Solution: Establish a cushion of at least 1/8'' and not more than 1/4''. Too little a cushion causes under-packing while too great a cushion results in uncontrolled packing of the sprue area.

Injection Hold Time Too Short

Explanation: Holding pressure is applied at the end of the injection stroke. The holding pressure is used for maintaining pressure against the molten material to pack it together while the skin solidifies. If the holding pressure is stopped too early, the still-molten material will leak back out of the cavity and pressure will be lost. Without the pressure, the layers of plastic cannot be fused together and they will pull apart as the molded part cools and shrinks.

Solution: Maintain the holding pressure until the gate freezes. Once that happens, the holding pressure will no longer have any effect on the material in the cavity.

MOLD

Sharp Corners In Gates And Runners

Explanation: Sharp corners, or 90 degree bends that are positioned along the flow path of runner system and gate, will shear the plastic as it goes by and tear the molecules apart. Breaking this bond results in the individual layers cooling at different rates and not bonding back together again in a proper manner. Delamination occurs when the part cools and shrinks.

Solution: It is always a good idea to utilize a radius at every turn in a runner system and at each gate entrance to the cavity. This will help to minimize shear and reduce the chance of resin separation during injection.

MATERIAL

Excessive Moisture

Explanation: Excessive moisture is one cause of delamination. It occurs because the water droplets actually turn to steam when heated in the injection unit, and this steam explodes throughout the plastic, interfering with molecular bonding, causing voided areas between molecules. This causes those areas to be extremely weak and brittle. The voided areas easily pull apart and delaminate when the part cools and shrinks.

Solution: Although it is commonly understood that non-hygroscopic material does not require drying, do not take chances. Dry all materials. It may be that fillers used in the material ARE hygroscopic and they will absorb moisture. Every plastic material requires specific drying conditions. And each material should be dried according to the material suppliers recommendations. The desired moisture content is between 1/10th of 1 percent and 1/20th of 1 percent by weight. This means the dry air being used to take moisture from the material should have a dew point of -20 to -40 degrees F.

OPERATOR

Excessive Mold Release

Explanation: Machine operators, who have been told to use mold release sprays sparingly, will eventually overuse the spray. The thought seems to be that if a little bit works, a lot will work better. Excessive mold release will interfere with molecular bonding of the plastic and cause weak layers that pull apart easily.

Solution: The remedy is to keep the mold as clean as possible and make every effort to eliminate the use of external mold releases.

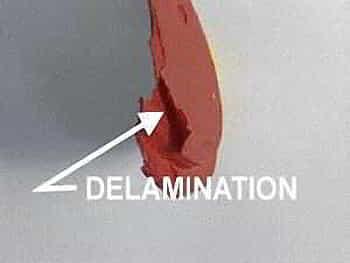

DELAMINATION

Delamination can be defined as a separation of the layers within a molded part. It can also appear as fish-scaling.

Some common causes and solutions are listed below.

Copyright by IPLAS and Douglas M. Bryce

Worldwide Rights Reserved

Worldwide Rights Reserved

NOTE: For more detailed information on the causes and solutions of this defect, you can find it in our BOOK, or ONLINE SEMINAR.